Upskill training material: a magnifying lens on the content of the manuals

- Federica Gallicchio

- Apr 29, 2021

- 2 min read

The training material of the Upskill Project will soon be available for free on our website.

The strenuous work carried out by the partners in this two and a half years long journey has given life to the Student’s and the Teacher’s books. Within the plastics industry, the manuals will now represent the vademecum for the development of the necessary digital, robotics, and other advanced manufacturing technology skills, and for the enhancement of environmental and entrepreneurial expertise.

The two manuals are functionally interrelated: similar in the structure and content, the distinctive added value of the Teacher’s manual is the addition of notes and suggestions addressed to the educators on how to best use the training material, handle the lessons and accompany the students throughout the entire learning process. One of the main obstacles in the delineation of a unified cross-border teaching/learning process has been, indeed, the different background of the educators. The issue has been tackled by adding those specific guidelines on how to make the best out of the material, in view of a modernisation not only of the competencies of the single student, but rather of the system as a whole.

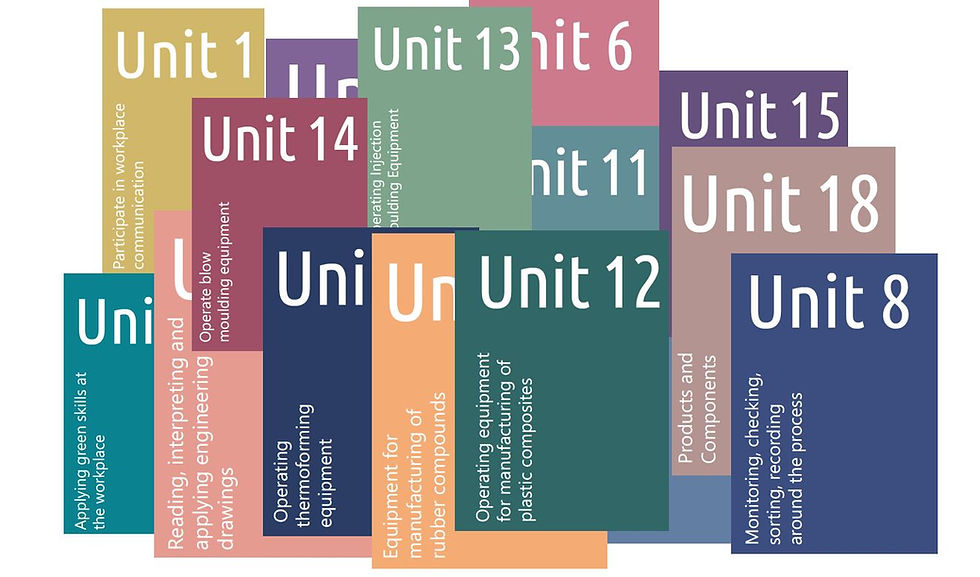

The manuals are divided into 18 different Units which comprise, inter alia, skills related to the enhancement of one’s contribution to the teamwork, the application of entrepreneurial and green skills, as well as lean manufacturing skills and quality, hygiene, safety rules at the work place. The technical know-how strictly related to the work within the plastic production line is instead covered by section 7, where the student is provided with the necessary tools to diagnose and solve a possible disfunction. The interpretation and application of engineering drawings, the ability to conduct a digitally operated system and the focus on the main characteristics of plastics materials are instead encompassed, respectively, within Unit 9, 10 and 11.

The following units revolve around the actual functioning and operating of the different types of equipment, namely: equipment for manufacturing of plastic composites, injection moulding, blow moulding, plastic extraction, thermoforming equipment as well as equipment for manufacturing of rubber compounds.

In order to make the learning process as smooth and consistent as possible, every Unit follows the same structure and is divided into 6 Sections:

Objectives, which lists the skills that the students will have acquired at the end of the learning process of the specific Unit

Investigation activity, which focuses on a practical case study, encouraging the student to find a solution to a possible problem

Documentary research, providing general information about an issue, requiring that the student run further research in order to develop additional know-how on the matter at hand

Practical activity, which describes a real-life scenario, providing the tool for its handling and resolution

Method sheet, which delineated a case, explaining how to identify the method and good practice related to the theme

Elements to remember, consisting of a brief overview of the knowledge acquired by the students through the study and the activities carried out in the context of the specific section.

Visit the Upskill website and download the training material!

The manuals will soon be available also in French, Lithuanian and Finnish.

Comments